What Is an Industrial Shaft? Types, Applications, and a Guide to Buying and Professional Repair

The industrial shaft is one of the key components in mechanical systems. In this article, we explore the different types of shafts, their applications, key considerations when purchasing, and industrial shaft repair services.

In any mechanical system where power transmission or movement occurs, the role of the industrial shaft is undoubtedly crucial. As a rotating axis, the shaft is responsible for transmitting torque and power between various components of machinery. A solid understanding of its function, types, and important points in purchasing and repair can significantly boost system efficiency and reduce maintenance costs.

What Is an Industrial Shaft?

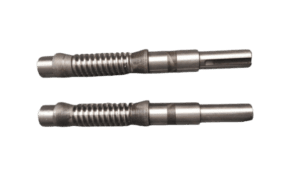

An industrial shaft is a cylindrical metal rod used to transfer power from one point to another in industrial equipment. It typically connects motors, gearboxes, couplings, bearings, and gears.

Types of Industrial Shafts

-

Plain Shaft

Features a smooth and uniform surface; used in general applications. -

Stepped Shaft

Has varying diameters at different sections to accommodate gears, pulleys, bearings, or couplings. -

Hollow Shaft

Used to reduce weight while maintaining torque transmission—ideal for industries such as automotive or lightweight machinery. -

Splined Shaft

Contains grooves for better engagement with other components like gearboxes or specialized couplings.

Materials Used for Industrial Shafts

Shafts are typically made from high-strength steel alloys. Common materials include CK45, ST52, stainless steel, or even aluminum for lighter applications. The shaft surface may undergo hardening, coating, or grinding treatments to enhance performance.

Applications of Industrial Shafts

-

Power transmission systems

-

Automotive industry

-

Mining and construction machinery

-

Conveyors and material handling systems

-

Gearboxes, pumps, and compressors

Key Considerations When Buying an Industrial Shaft

-

Material and durability: Must withstand pressure and wear.

-

Length and diameter: Should meet engineering specifications.

-

Surface finish: Ground or unground surface depending on requirements.

-

Precision tolerance: In accordance with DIN or ISO standards.

-

Compatibility: Ability to mount couplings or bearings properly.

Industrial Shaft Repair and Manufacturing Services

Sometimes, due to factors like impact, corrosion, or bending, a shaft may require repair or replacement. Repair services may include:

-

Straightening and alignment

-

Welding and surface restoration

-

Regrinding or machining

-

Manufacturing a new shaft based on a sample or technical drawing

🔧 If your shaft is damaged, we offer high-precision shaft manufacturing, repair, and replacement services with quality assurance.

Conclusion

As one of the essential components in power transmission systems, the industrial shaft plays a decisive role in the proper operation of machinery. Carefully selecting the right shaft and performing regular maintenance can greatly enhance system efficiency. If you’re looking to purchase or repair a high-quality industrial shaft, feel free to contact us.